The NIMBLER™ Platform

- Category AI & Robotics

- Industry Multiple

- Maturity TRL 9: Actual System Proven in Operational Environment

Reliable inspection access for the spaces that matter most.

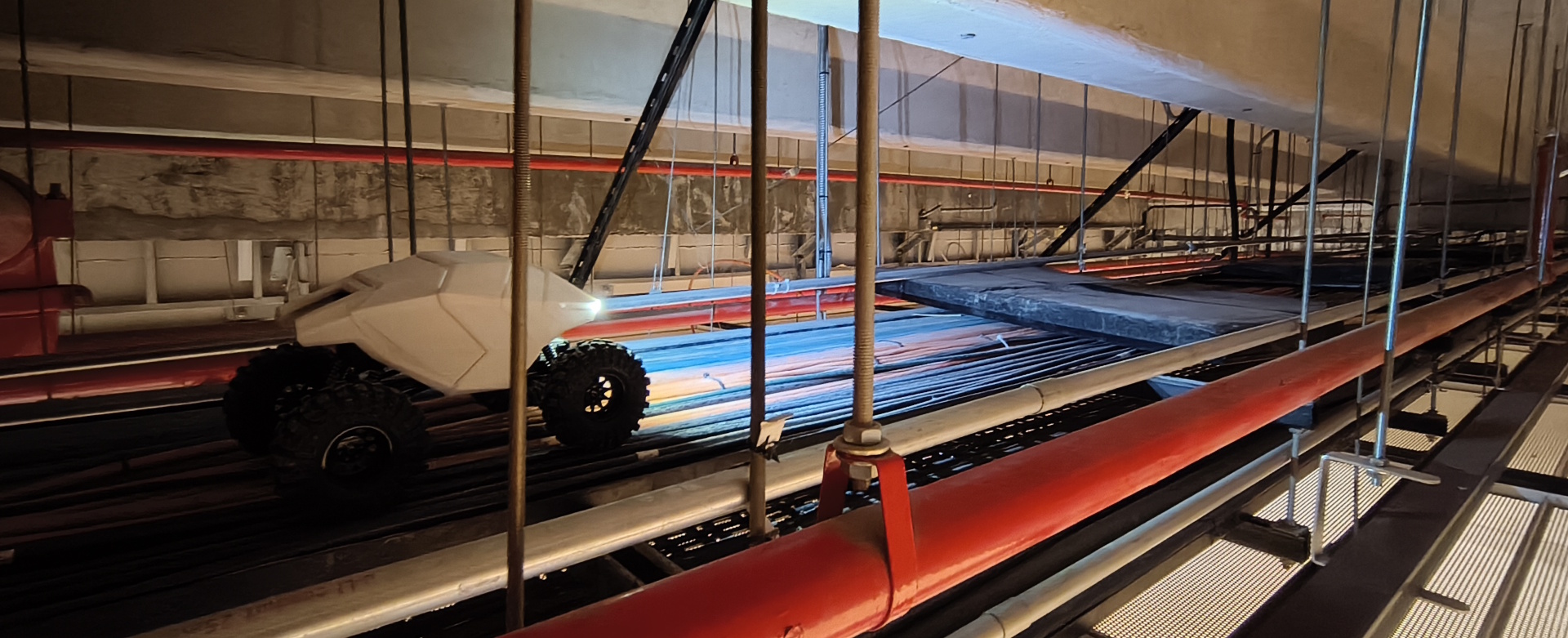

NIMBLER™ is a robotic inspection platform designed to provide consistent, close-proximity visual access to constrained and inaccessible spaces within buildings and infrastructure. These spaces—often critical to structural integrity, safety, and long-term performance—are rarely inspected due to access difficulty, safety risk, or operational disruption.

Developed by MyrLabs and proven in live environments, NIMBLER™ enables inspections that are safer, more repeatable, and more defensible across the asset lifecycle.

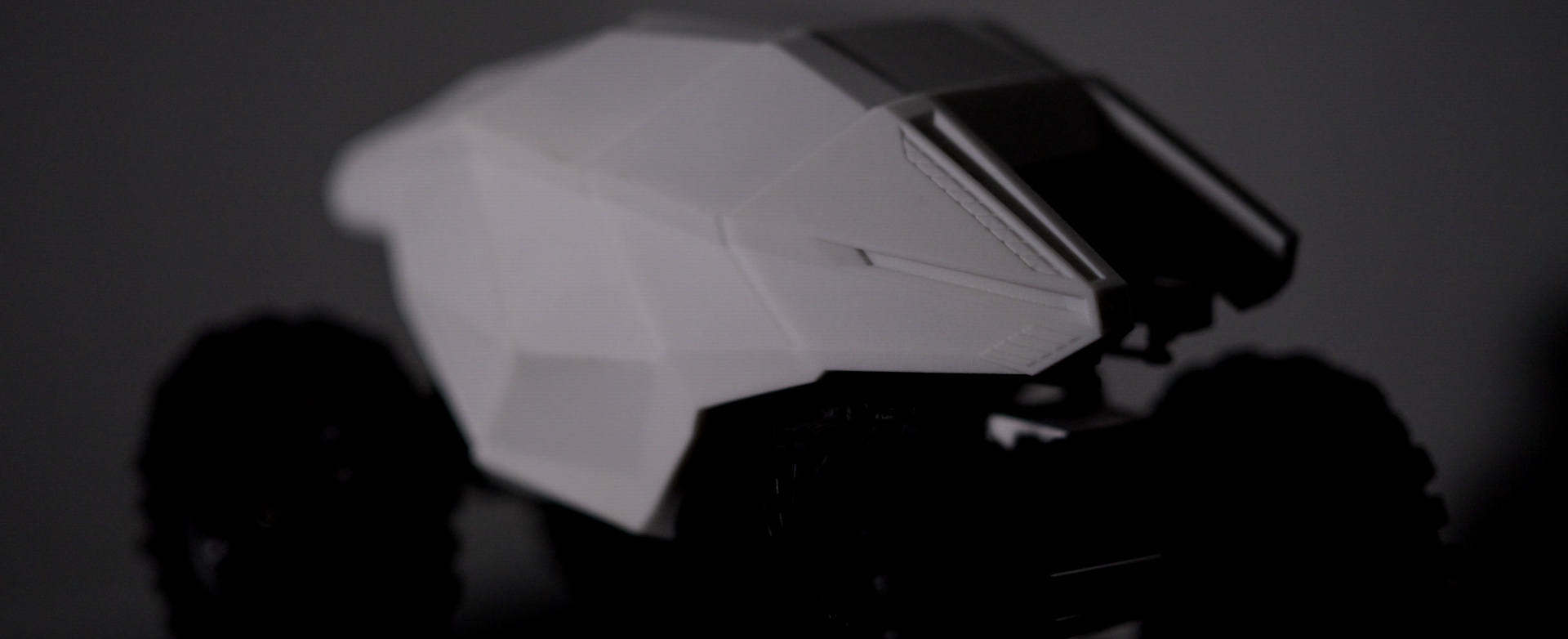

Purpose-built for inspection.

NIMBLER™ is engineered for inspection tasks in confined environments where precision, stability, and proximity matter.

Its adaptive robotic architecture allows it to:

Navigate tight clearances and congested layouts

Maintain stability on uneven or debris-covered surfaces

Reconfigure its body to overcome obstructions without forcing access

Designed to support engineering judgment.

NIMBLER™ captures full-colour 1080p visual data at close range, enabling detailed inspection of conditions that are difficult to assess remotely, including:

Cracks, spalling, and surface degradation

Corrosion and material deterioration

Water ingress and efflorescence

Cable routing, fixings, and interfaces

Because the platform can be redeployed consistently, inspections can be repeated over time to support comparison, condition tracking, and documentation—rather than isolated visual checks.

Why Constrained Spaces Matter.

Key structural, mechanical, and safety-related elements are frequently located in areas that are difficult or unsafe to access:

Above False or Suspended Ceilings

Beneath Roofs and Secondary Roofs

Beneath Raised Flooring

Inside Drains and Utility Systems

Limited access often results in infrequent inspection, incomplete visibility, or reliance on assumptions. Over time, this creates blind spots that affect structural performance, regulatory compliance, and asset value.

NIMBLER™ is designed to close these gaps by making constrained spaces inspectable as part of routine operations

Supporting inspectors, not replacing them

Built-In Intelligence.

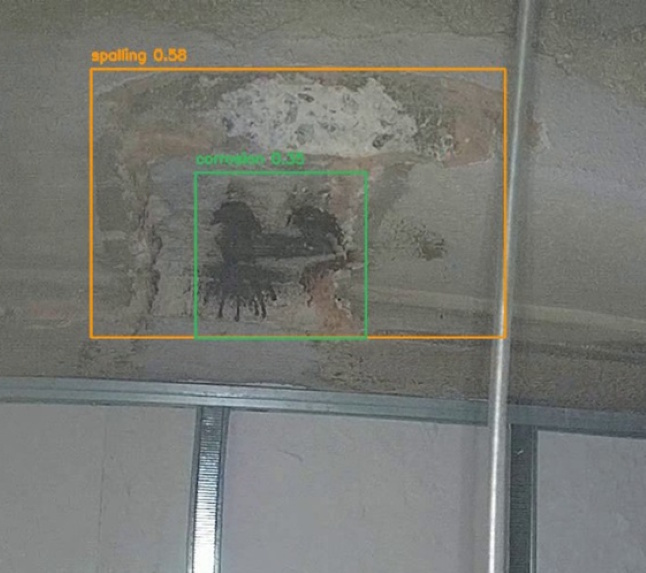

NIMBLER™ integrates onboard AI to assist with visual analysis during inspection. The system highlights potential anomalies in real time, helping inspection teams focus attention on areas that warrant closer review.

Detection capabilities include:

Spalling

Corrosion

Efflorescence

Vegetation

Cracks

Debris

Trash

AI models are constantly updated to reflect new camera and defect types. Final assessment and judgment remain with qualified professionals.

Applicable Across the Asset Lifecycle.

NIMBLER™ supports inspection needs at multiple stages:

Post-construction and handover: Verification of as-built conditions

Routine operations: Periodic inspection without disruption

Condition assessment: Targeted investigation of suspected issues

Lifecycle management: Trend observation and early fault detection

Its ability to operate without scaffolding, shutdowns, or intrusive access makes it suitable for both new and occupied buildings.

Understanding the trade-offs.

Different inspection approaches serve different needs. Most organizations rely on a combination of methods depending on access, risk, and inspection objectives.

Manual Access

Manual inspections allow direct intervention but require significant setup, safety controls, and access preparation. As a result, they are often reserved for corrective work or infrequent checks rather than routine monitoring.

Aerial Tools (Drones)

Drones are effective for large, open, and visually unobstructed spaces. Their usefulness decreases in enclosed or cluttered environments where proximity, stability, and line-of-sight are limited.

Constrained-Space Crawlers (NIMBLER™)

Crawlers like NIMBLER™ are designed for environments where manual entry is impractical and aerial tools are ineffective. They enable close-proximity inspection with reduced safety exposure and consistent documentation, making them suitable for regular inspection programs.

Developed for Real Infrastructure

NIMBLER™ is developed by MyrLabs in Singapore. The platform is backed by sustained research, field testing, and real-world deployments, not laboratory-only demonstrations. Patents pending.

Operational and Regulatory Benefits.

Reduced safety exposure for inspection personnel

Improved consistency and repeatability of inspections

Better documentation for reporting and regulatory compliance purposes

Reduced disruption to building occupants and operations

Earlier detection of defects before escalation

By making constrained-space inspections routine and repeatable, NIMBLER™ supports more informed decision-making across engineering, regulatory, and ownership stakeholders.

Where NIMBLER™ Is Used

NIMBLER™ is used for inspection of concealed, hard-to-access, and high-risk areas commonly found within buildings. These areas are frequently recorded as inaccessible or excluded during inspections due to physical constraints, safety considerations, or the disruption required to gain access using conventional methods.

Such areas commonly include:

Above-Ceiling and Service Voids

Roof and Secondary Roof Areas

Beneath Raised Flooring

Drain and Utility Systems

NIMBLER™ enables safe, repeatable visual access to these environments—reducing the need to designate areas as excluded and supporting more complete, defensible inspection coverage over time.

Making Hidden Infrastructure Visible

Representative inspection imagery captured in live building environments using NIMBLER™.

Frequently Asked Questions

NIMBLER™ is currently offered under a Robot-as-a-Service (RaaS) model. Direct sales of the platform are planned for the future.

The daily service rate for NIMBLER™ is benchmarked at approximately 75%–95% of the prevailing daily rate for a PSI-qualified engineer, depending on deployment scope and site conditions. Each deployment includes two trained NIMBLER™ operators, ensuring safe operation, efficient inspection coverage, and reliable data capture during live deployments.

Preference rates may be extended to partners who participate in data-sharing initiatives or who showcase inspection outcomes as part of joint industry learning and capability development.

The NIMBLER™ robots come in 2 sizes -- SMALL and MEDIUM.

The SMALL NIMBLER™ has a dimension of 190L x 110W x 90-120H mm with a weight of 600g; the MEDIUM NIMBLER™ is 320L x 220W x 150-220H mm with a weight of 1,500g.

Both sizes of robots have an operating time of ~45mins before needing a battery change.

No. NIMBLER™ does not replace statutory inspection requirements or the professional judgment of appointed engineers or competent persons.

It is a tool that supports inspection workflows by improving access, visibility, and documentation in constrained spaces. Final assessment, certification, and regulatory submissions remain the responsibility of the appointed professionals and building owners.

Regulatory acceptance is based on inspection outcomes, evidence quality, and professional accountability, not the specific tool used.

NIMBLER™ has been publicly showcased at two industry trade shows and featured in two industry sharing sessions organised by the Building and Construction Authority (BCA). These forums are typically attended by regulators, professional engineers, building owners, and industry practitioners, and are intended to surface emerging inspection approaches and technologies relevant to the built environment.

In practice, NIMBLER™ supports regulatory expectations by improving access to constrained spaces, enabling safer inspection workflows, and producing clearer, more consistent inspection records. Acceptance of inspection findings continues to rest with the appointed professionals and remains subject to applicable regulations, codes, and professional standards.

Adoption has been driven primarily by owners, engineers, and operators seeking safer and more complete access to concealed spaces, rather than by changes to regulatory requirements.

In many deployments, NIMBLER™ has eliminated the need for manual entry by providing reliable visual access to confined or obstructed spaces that were previously unsafe or impractical for personnel to enter.

The platform has enabled inspections in areas where human entry was not feasible due to clearance, safety, or operational constraints, allowing inspection teams to obtain meaningful visual information without exposing personnel to confined-space hazards.

Where inspection objectives can be met through visual assessment, NIMBLER™ can be used in place of manual entry. However, when physical intervention, tactile assessment, or remedial works are required, human entry may still be necessary and must comply with applicable safety and permit requirements.

NIMBLER™ is therefore best understood as a tool that reduces or removes the need for manual entry for inspection and scoping purposes, while supporting safer, more targeted decisions on when human access is genuinely required.

NIMBLER™ is designed to position itself in close proximity to inspection targets, even within tight, cluttered, or obstructed spaces. Its adaptive form and controlled movement allow the platform to approach areas of interest directly, rather than relying on distant or indirect views.

For situations where physical proximity is limited, NIMBLER™ is available in variants equipped with 4× zoom cameras, enabling detailed visual inspection without requiring contact or further access preparation. Selected variants also incorporate thermal imaging, supporting the identification of temperature differentials associated with moisture ingress, insulation issues, or abnormal heat patterns.

The combination of close-range positioning, optical zoom, and thermal sensing allows inspection teams to obtain meaningful visual and thermal information across a range of constrained conditions, while maintaining a safe and controlled inspection process.

NIMBLER™ captures inspection data through onboard visual and sensing systems designed for close-range assessment in constrained environments. Depending on inspection objectives, the platform can be deployed with different camera and sensor configurations to ensure meaningful data capture under varying access conditions.

Standard configurations include a high-resolution full-colour visual camera optimised for close-proximity inspection in low-light and confined spaces. Where physical proximity to the inspection target is limited, NIMBLER™ is available in variants equipped with a 4× zoom camera, allowing inspectors to examine fine details, such as cracks, corrosion, fixings, or surface degradation—without requiring additional access preparation.

Selected variants also incorporate thermal imaging, which can support the identification of temperature differentials associated with moisture ingress, insulation discontinuities, or abnormal heat patterns. Thermal data is used as a supplementary input and is interpreted alongside visual observations by qualified professionals.

During deployment, visual and thermal data are recorded and can be reviewed, annotated, and retained as part of inspection records. Depending on inspection scope, visual and thermal information may be captured in the same inspection exercise or through separate passes to support correlation and clearer assessment.

The resulting inspection records provide:- 1. Clear visual evidence of inspected conditions

- 2. Traceable documentation of inspection coverage

- 3. Improved communication between engineers, owners, and regulators

NIMBLER™ enhances the quality and consistency of inspection documentation, but it does not replace professional judgment or statutory responsibilities. Interpretation of inspection data, reporting, and regulatory submissions remain the responsibility of the appointed professionals and building owners.

No. NIMBLER™ uses AI to assist with visual analysis by highlighting potential anomalies during inspection.

AI does not make inspection decisions or replace professional judgment. It functions as a decision-support tool to help inspection teams focus attention on areas that may warrant closer review.

AI models used by NIMBLER™ are constantly updated to reflect new camera and defect types.

The AI model currently supports visual identification of a range of conditions commonly assessed during building and infrastructure inspections, including:- 1. Cracks, spalling, and surface deterioration

- 2. Corrosion and material degradation

- 3. Moisture ingress and efflorescence

- 4. Insulation defects and discontinuities

- 5. Debris accumulation and foreign objects

- 6. Installation issues in services and fixtures

Updates are managed to ensure consistency with inspection objectives and do not override professional assessment processes.

- 1. Above-ceiling and service voids

- 2. Roof and Secondary Roof Areas

- 3. Beneath Raised Flooring

- 4. Drain and Utility Systems

- 1. Airports

- 2. Retail Malls

- 3. Large Office Buildings and Flatted Factories

- 4. Public Housing and Condominium Blocks

- 5. Public Drains and Canals

Suitability for specific environments depends on site conditions, inspection objectives, and deployment constraints.

No. The use of NIMBLER™ does not alter statutory responsibilities, professional accountability, or regulatory obligations.

It can support better-informed decision-making by improving access, consistency, and documentation, helping stakeholders demonstrate due diligence when used within established inspection processes.

NIMBLER™ is designed to be deployed with minimal disruption to occupied buildings, including inspections conducted while spaces remain in active use.

In several deployments, compact NIMBLER™ variants have been introduced into above-ceiling spaces through existing light-fixture openings, avoiding additional access cuts or removal of ceiling panels. Inspections have been conducted while occupants were present beneath the false ceiling, with inspection activity contained above the ceiling line.

This reduces the need for cordoning, after-hours work, or tenant displacement.

Operation is typically carried out by trained operators. Inspection planning, interpretation, and reporting remain the responsibility of qualified engineers or appointed professionals.

Yes. Repeated inspections using NIMBLER™ can support condition tracking and trend observation over time.

When used alongside established asset management frameworks, inspection data can inform maintenance planning, risk prioritisation, and lifecycle decision-making.

Different tools serve different inspection needs.

Drones are effective in open or visually unobstructed spaces, while crawlers like NIMBLER™ are designed for enclosed, cluttered environments where proximity and stability are critical.

NIMBLER™ is designed to be applicable across the majority of building types where concealed or constrained spaces exist.

Above ceilings, within service voids, crawl spaces, secondary roofs, drainage systems, and other concealed areas are common across residential, commercial, institutional, and industrial buildings. NIMBLER™ is engineered to operate in these environments and has been deployed in a wide range of building conditions without requiring building-specific customization.

In most cases, NIMBLER™ can be integrated directly into existing inspection workflows with minimal preparation. Rather than determining whether the platform is suitable, the discussion typically focuses on which inspection objectives and configurations (visual, zoom, thermal) best support the site’s needs. MyrLabs supports this alignment through a short technical discussion.